Weld Procedure Template

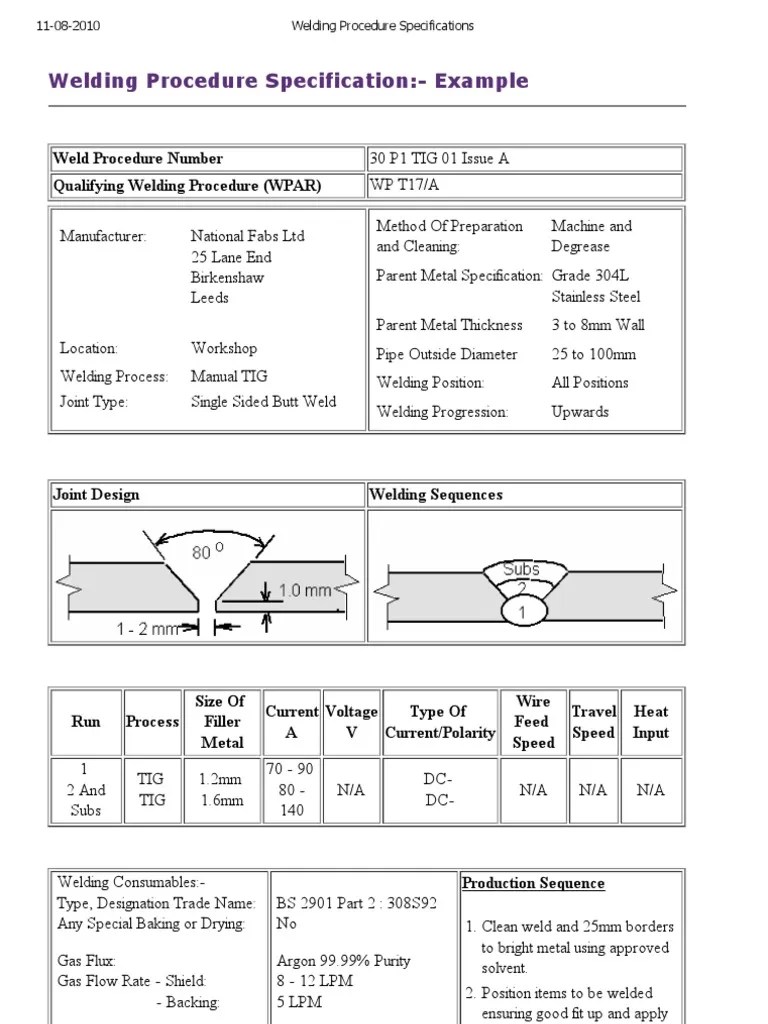

Weld Procedure Template - Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. These settings are not visible to the welder with the hood down. The sample welding procedure specification (wps) form is used to document the details and. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence.

Welding Procedure Specification Template

A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. These settings are.

Welding Procedure TWI

Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. These settings are not visible to the welder with the hood down. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence. Sample form for welding procedure specification (wps) company name_____ wps.

Welding Procedure Specification Template

The sample welding procedure specification (wps) form is used to document the details and. Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel.

Welding Procedure Specification Template

These settings are not visible to the welder with the hood down. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. Pass process filler metal current (asme sec iic) heat input (kj/mm).

Fillable Form A2 Sample Welding Procedure Specification (Wps) Form

Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. These settings are not visible to the welder with the hood down. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence. A welding wps document, also called a welding procedure specification,.

STANDARD FORMAT FOR WELDING PROCEDURE SPECIFICATION (WPS)

A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. These settings are not visible to the welder with the hood down. Sample form for welding procedure.

Example WPS Download Welding Procedures

Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that.

Welding Procedure Specification Template

The sample welding procedure specification (wps) form is used to document the details and. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sample form for.

Welding Procedure Specification (ASME Section IX 2019 Edition

Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. The sample welding procedure specification (wps) form is used to document the details and. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. These settings are not visible to the welder with.

Weld Procedure Specification Gtaw Pipe

Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence. These settings are not visible to the welder with the hood down. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. The sample welding procedure specification (wps) form.

Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. These settings are not visible to the welder with the hood down. The sample welding procedure specification (wps) form is used to document the details and. A welding wps document, also called a welding procedure specification, describes the welding process, materials, and procedures for producing a weld that meets. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence.

The Sample Welding Procedure Specification (Wps) Form Is Used To Document The Details And.

Sample form for welding procedure specification (wps) company name_____ wps no._____ rev._____ date_____ supporting. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple. These settings are not visible to the welder with the hood down. Pass process filler metal current (asme sec iic) heat input (kj/mm) travel speed (mm/min) joint details run sequence.